Maximizing Engine Potential: Exploring the Valve Timing Diagram of Four-Stroke Engines

Valve timing is like the heartbeat of a four-stroke engine. Just as our heart beats rhythmically to pump blood through our body, valves in an engine open and close at specific times to let air and fuel in and push exhaust gases out. This timing is super important because it affects how smoothly the engine runs and how much power it produces.

In this blog, we’ll dive into why valve timing matters so much for four-stroke engines. We’ll talk about how it works, why engineers pay so much attention to it, and how it can make your engine run better. So, get ready to learn all about the fascinating world of valve timing and how it shapes the performance of your favorite machines!

Theoretical Valve Timing

Valve timing in a four-stroke engine is like a choreographed dance between the engine’s components, ensuring each stroke happens at just the right moment for optimal performance. Let’s break down the theoretical valve timing and understand how it influences the engine’s operation.

Four Strokes: Suction, Compression, Power, and Exhaust

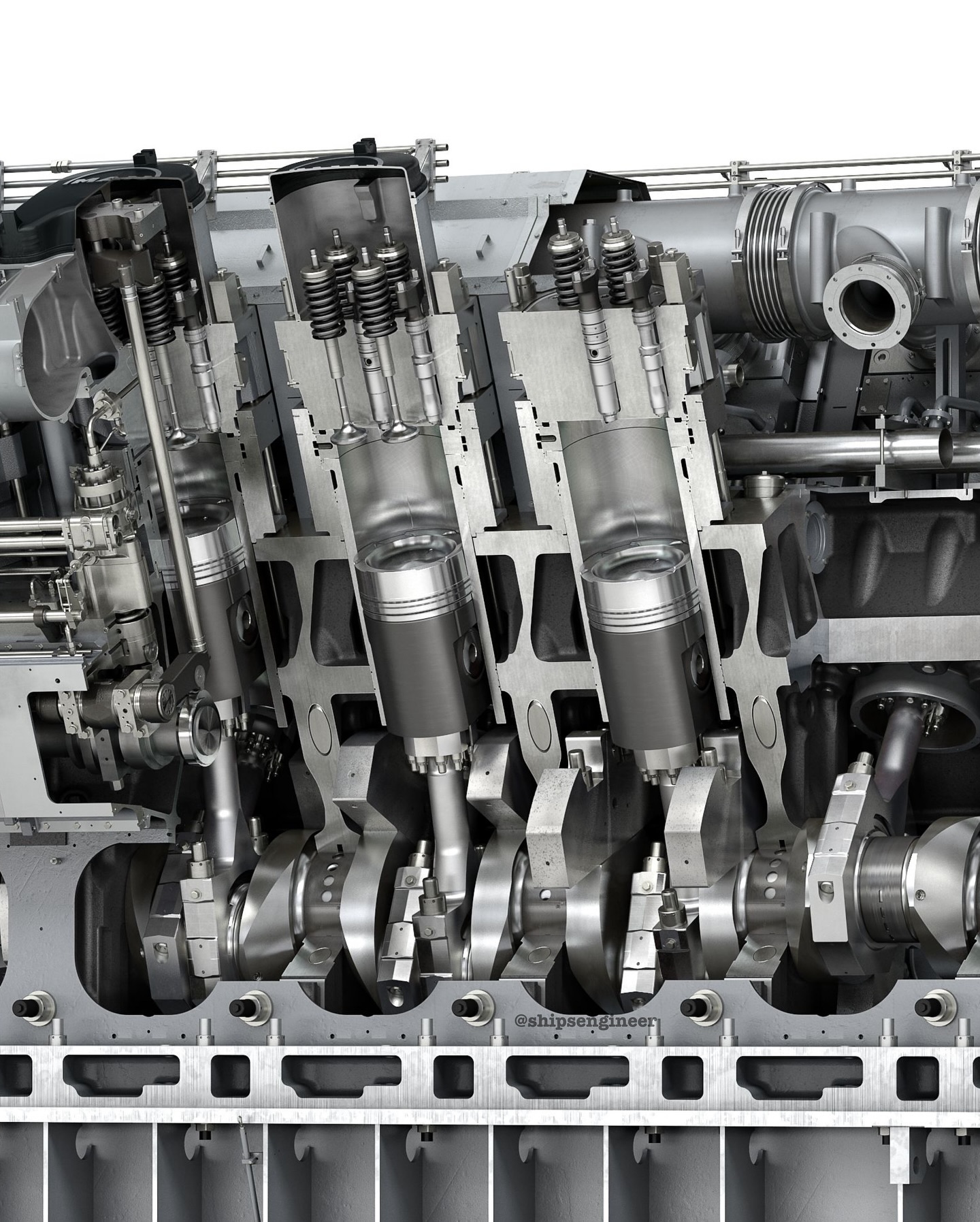

- Suction Stroke: This is the first stroke in the cycle where the piston moves down from the top of the cylinder (top dead center or T.D.C.) to the bottom (bottom dead center or B.D.C.). During this stroke, the inlet valve opens, allowing a mixture of air and fuel to enter the cylinder as the piston creates a vacuum. This mixture is essential for the combustion process.

- Compression Stroke: Following the suction stroke, the piston moves back up from B.D.C. to T.D.C., compressing the air-fuel mixture in the cylinder. Both the inlet and exhaust valves remain closed during this stroke. As the cylinder’s volume decreases, the mixture’s pressure and temperature increase, preparing it for combustion.

- Power Stroke: The power stroke is where the magic happens. With the air-fuel mixture compressed to its maximum, a spark plug ignites the mixture, causing a controlled explosion. This explosion forces the piston down from T.D.C. to B.D.C. with significant force, generating the power needed to drive the engine.

- Exhaust Stroke: Finally, the exhaust stroke completes the cycle. As the piston moves back up from B.D.C. to T.D.C., the exhaust valve opens, allowing the burnt gases from the combustion process to escape the cylinder. This prepares the cylinder for the next intake cycle.

Understanding these four strokes is crucial because they dictate when the valves need to open and close to facilitate each stage of the combustion process effectively. Each stroke builds upon the previous one, creating a continuous cycle of energy conversion within the engine.

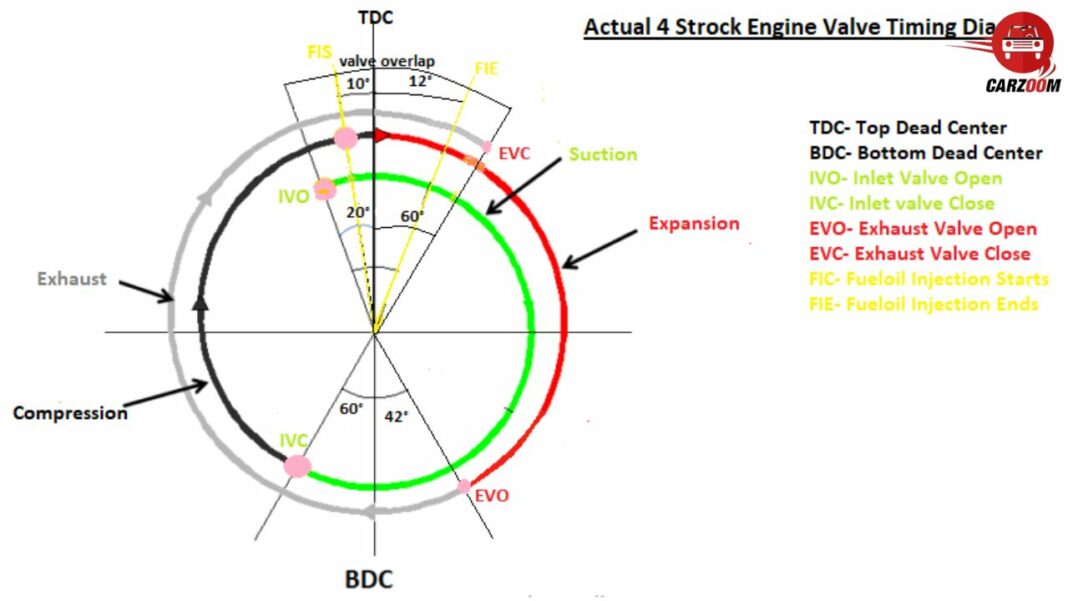

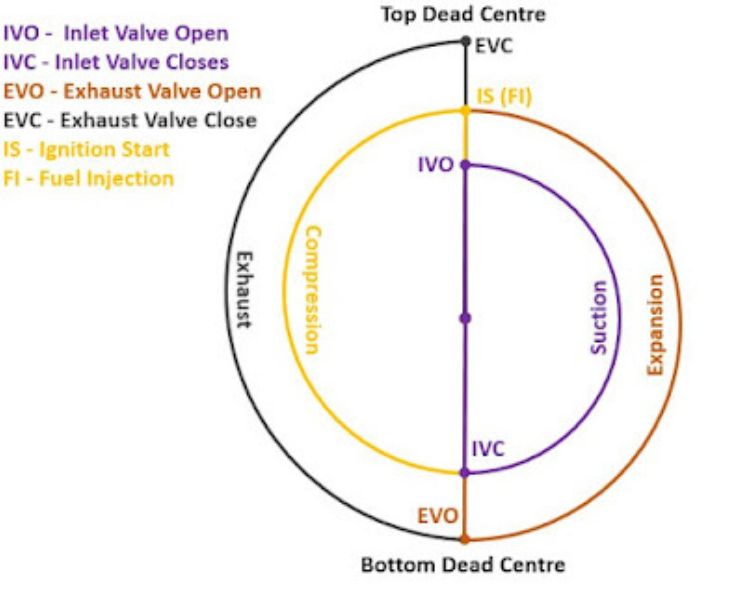

Graphical Representation of Theoretical Valve Timing Diagram

Visualizing the theoretical valve timing diagram provides a clear picture of how the engine’s components work together during each stroke. In this diagram, the position of the piston and the timing of the valve openings and closings are plotted against the rotation of the crankshaft.

- Inlet Valve Timing: The diagram shows the precise moment when the inlet valve opens at the start of the suction stroke and closes at the end of the stroke. This ensures that the cylinder receives the right amount of air-fuel mixture for combustion.

- Exhaust Valve Timing: Similarly, the diagram illustrates when the exhaust valve opens at the beginning of the exhaust stroke and closes at the end, allowing for the expulsion of burnt gases.

By studying this graphical representation, engineers can fine-tune the timing of the valves to optimize engine performance, efficiency, and emissions.

Actual Valve Timing

Actual valve timing refers to the timing of the opening and closing of valves in a four-stroke engine under real-world conditions. Unlike theoretical valve timing, which is idealized, actual valve timing considers various factors that affect how valves operate in practice. Let’s break down what influences actual valve timing and why it’s important.

Factors Influencing Actual Valve Timing

Several things can affect when valves open and close in a real engine:

- Engine Speed: How fast the engine is running affects when valves need to open and close. A faster engine needs quicker valve movements to keep up with the pace.

- Torque Needs: The amount of twisting power the engine needs at different times can change when valves should open and close. More torque might mean adjusting valve timing for better performance.

- Atmospheric Pressure: Changes in air pressure, like those caused by altitude or weather, can affect how much air goes into the engine. Valve timing might need adjusting to keep the engine running smoothly despite these changes.

- Engine Load: Whether the engine is idling, cruising, or working hard affects valve timing. Different situations might call for different valve timings to keep the engine running efficiently.

- Valve Train Design: The parts that control the valves, like camshafts and springs, also play a role. Different designs might mean different valve timing behaviors.

By taking these factors into account, engineers can make sure the engine’s valves open and close at just the right times for the best performance and efficiency.

Comparison Between Theoretical and Actual Valve Timing Diagrams

| Aspect | Theoretical Valve Timing Diagrams | Actual Valve Timing |

| Real-World Considerations | Based on idealized conditions without accounting for wear and tear on engine parts | Deals with wear and tear on engine components, which can impact valve behavior |

| Dynamic Effects | Typically overlooks dynamic effects such as valve bouncing at high engine speeds | Accounts for dynamic effects like momentary valve bouncing during fast engine operation |

| Environmental Effects | Does not consider environmental factors like temperature and humidity | Takes into account changes in engine behavior due to environmental conditions |

| Utility | Useful for understanding basic engine principles | Essential for ensuring smooth engine operation under real-world conditions |

Despite these differences, theoretical valve timing diagrams are still useful for understanding engine basics. But actual valve timing takes into account the quirks of real engines and helps them run smoothly.

Significance of Engine Speed, Torque, and Atmospheric Pressure

Engine speed, torque needs, and atmospheric pressure all affect how valves operate and, in turn, how the engine performs:

- Engine Speed: Faster engines need quicker valve movements to keep up. Adjusting valve timing for different speeds helps the engine stay stable and powerful.

- Torque Needs: Different situations might call for more or less torque. Adjusting valve timing helps deliver the right amount of power when it’s needed.

- Atmospheric Pressure: Changes in air pressure can affect engine performance. Adjusting valve timing helps the engine run smoothly regardless of these changes.

By understanding how these factors affect valve timing, engineers can make sure engines run efficiently and reliably in all sorts of conditions.

Inlet Valve Timing

The inlet valve in an engine controls the entry of air and fuel mixture into the combustion chamber. Its timing is crucial for optimal engine performance.

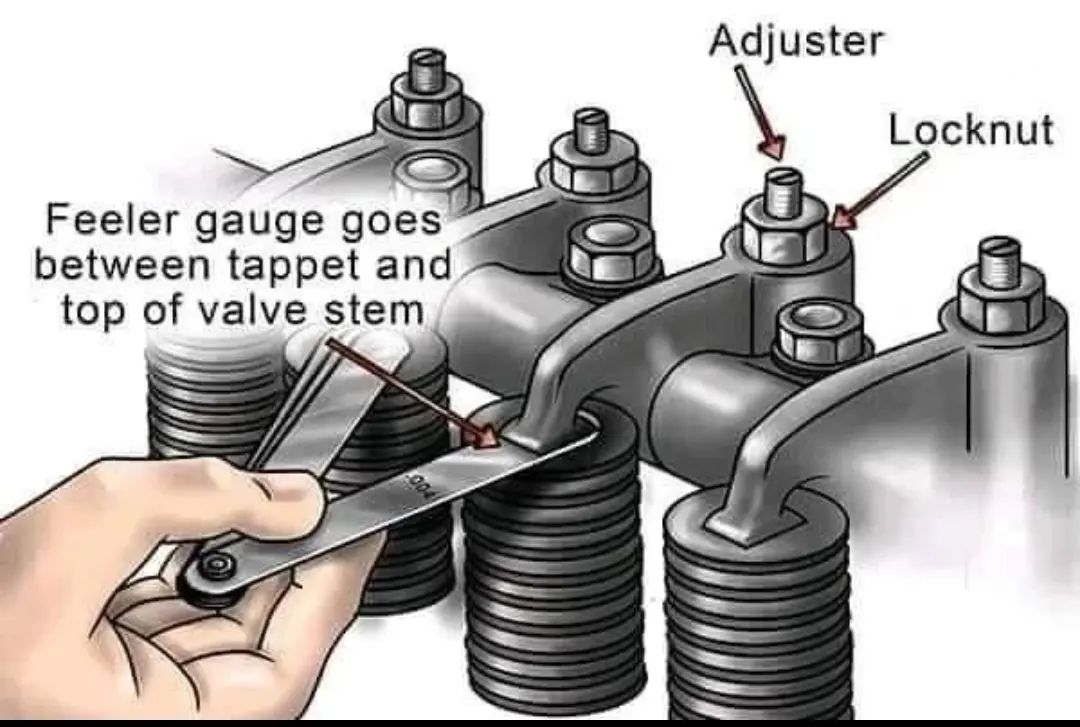

Opening and Closing Moments of the Inlet Valve

- The inlet valve opens to allow the air-fuel mixture to enter the combustion chamber during the suction stroke.

- It typically starts to open a few degrees before the piston reaches top dead center (T.D.C.) and remains open for a specific duration to ensure sufficient intake of the air-fuel mixture.

- The valve then closes before the compression stroke begins, sealing the combustion chamber to prevent any leakage of the mixture.

Effects of Pre-Admission and Post-Admission Timing

- Pre-admission timing refers to the period before the piston reaches T.D.C., where the inlet valve begins to open. This timing ensures that the valve is fully open when the piston starts its downward stroke, allowing maximum airflow into the cylinder.

- Post-admission timing occurs after the piston passes T.D.C., where the inlet valve remains open during the early stages of the compression stroke. This allows for additional intake of the mixture to compensate for any pressure drop inside the cylinder.

Real-World Examples and Timing Data

- In real-world engine designs, the inlet valve timing is carefully optimized to balance factors like engine speed, torque requirements, and efficiency.

- For example, in a popular engine model, the inlet valve may start to open a few degrees before T.D.C. and remain open for a specific duration during the suction stroke.

- The timing data for the inlet valve opening and closing are critical parameters that engineers consider during engine design and tuning processes to achieve the desired performance characteristics.

Understanding the inlet valve timing helps engineers optimize engine operation for improved power output, fuel efficiency, and emissions control. By fine-tuning the timing parameters, engines can achieve better overall performance and reliability.

Exhaust Valve Timing

The exhaust valve in an engine controls the release of exhaust gases from the combustion chamber. Its timing is crucial for efficient engine operation and emissions control.

Opening and Closing Moments of the Exhaust Valve

- The exhaust valve opens to allow the exhaust gases to exit the combustion chamber during the exhaust stroke.

- It typically starts to open a few degrees before the piston reaches bottom dead center (B.D.C.) and remains open for a specific duration to ensure complete expulsion of the exhaust gases.

- The valve then closes before the intake stroke begins, sealing the combustion chamber to prevent any backflow of exhaust gases.

Impact of Pre-Release Timing on Engine Performance

- Pre-release timing refers to the period before the piston reaches B.D.C., where the exhaust valve begins to open. This timing ensures that the valve is fully open when the piston starts its upward stroke, allowing for efficient expulsion of the exhaust gases.

- Proper pre-release timing helps reduce backpressure in the exhaust system, allowing the engine to breathe more freely and improving overall performance.

Timing Data for Exhaust Valve Operations

- In real-world engine designs, the exhaust valve timing is carefully optimized to balance factors like engine speed, torque requirements, and emissions regulations.

- For example, in a popular engine model, the exhaust valve may start to open a few degrees before B.D.C. and remain open for a specific duration during the exhaust stroke.

- The timing data for exhaust valve opening and closing are crucial parameters that engineers consider during engine design and tuning processes to achieve the desired performance characteristics while meeting emissions standards.

By adjusting the timing parameters, engines can achieve better power delivery, fuel efficiency, and reduced emissions, contributing to overall environmental sustainability.

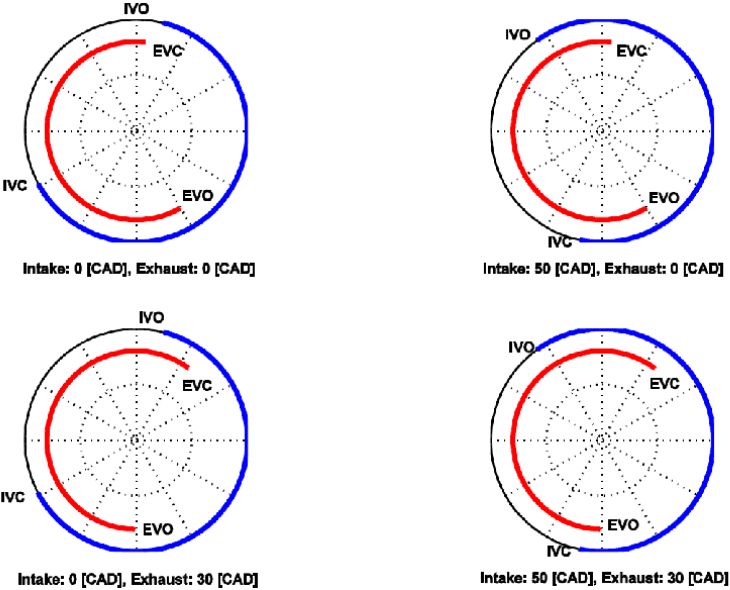

Optimizing Valve Timing for Engine Efficiency

Achieving optimal valve timing is crucial for maximizing engine performance, fuel efficiency, and overall reliability. Here’s how engineers optimize valve timing to achieve these goals:

Strategies for Maximizing Power Output

- Fine-tuning valve Timing: Engineers utilize advanced techniques and simulations to fine-tune valve timing parameters such as the duration and phasing of valve events. This optimization ensures that valves open and close at the most opportune moments during the engine cycle, maximizing power output.

- Utilizing Variable Valve Timing (VVT): Modern engines often employ variable valve timing systems that can adjust valve timing in real time based on engine speed, load, and other operating conditions. VVT systems optimize valve timing for both low-end torque and high-end power, enhancing overall engine performance.

- Optimizing Camshaft Profiles: The design of the camshaft profiles significantly influences valve timing. Engineers carefully design cam profiles to achieve the desired valve lift and duration, optimizing power delivery across the engine’s operating range.

Importance of Proper Valve Timing Adjustment

- Enhanced Combustion Efficiency: Proper valve timing ensures that the air-fuel mixture is efficiently combusted within the cylinder, maximizing energy conversion and minimizing fuel consumption. By precisely controlling valve events, engine efficiency is improved, leading to better fuel economy.

- Reduced Emissions: Optimal valve timing plays a critical role in emissions control by promoting complete combustion and efficient exhaust gas scavenging. Properly adjusted valve timing minimizes unburned hydrocarbons, carbon monoxide, and nitrogen oxide emissions, contributing to environmental sustainability.

- Enhanced Engine Reliability: Improper valve timing can lead to issues such as valve overlap, where intake and exhaust valves are open simultaneously, resulting in reduced engine efficiency and potential damage. Correct valve timing adjustment ensures smooth engine operation, prolonging engine life and reliability.

Optimizing valve timing is essential for achieving peak engine performance, fuel efficiency, and emissions control. By employing advanced strategies and technologies for valve timing adjustment, engineers can unlock the full potential of modern engines while ensuring their long-term reliability and environmental sustainability.

Conclusion

Valve timing is a critical aspect of engine design and performance optimization in four-stroke engines. Throughout this exploration, we’ve delved into the theoretical and actual aspects of valve timing, understanding its importance and intricacies.

Theoretical valve timing diagrams provide a foundational understanding of how valves operate in ideal conditions, guiding engineers in conceptualizing engine designs. However, actual valve timing considers real-world factors such as engine speed, torque demands, and environmental conditions, ensuring optimal valve operations under varying circumstances.

Furthermore, we’ve examined the significance of both inlet and exhaust valve timing, recognizing their roles in facilitating air-fuel mixture intake and exhaust gas expulsion, respectively. By fine-tuning valve timing parameters and utilizing advanced technologies like Variable Valve Timing (VVT), engineers can maximize engine power output, fuel efficiency, and emissions control.

Proper valve timing adjustment not only enhances combustion efficiency and reduces emissions but also contributes to the overall reliability and longevity of the engine. Through meticulous optimization of valve timing strategies, engines can achieve peak performance while meeting stringent environmental regulations.

How much did you like Our detailed Valve timing diagram of four stroke diesel engine? Review Also, please share these Blogs with your friends on social media.

Recommended